Anchors are available in three sizes. As the size of the anchor increases, working load and ultimate resistance increase:

- F80

- Zinc Die Cast

- Surface Area: 3.4 in²

- F120

- Zinc Die Cast

- Surface Area: 6 in²

- F170

- Zinc Die Cast

- Surface Area: 12.2 in²

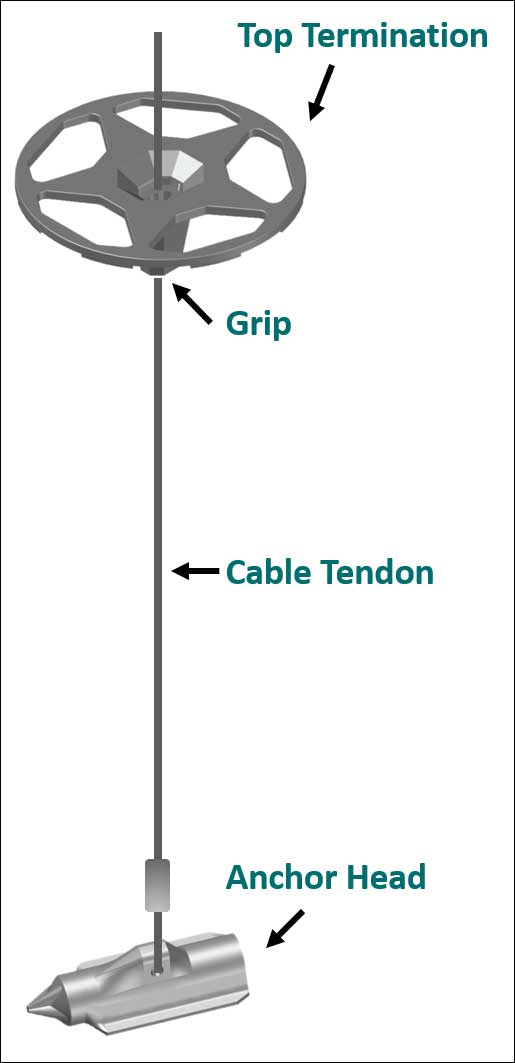

Top Terminations are available in 2 sizes. Durability and working load increase with size.

The top termination uses a unique design to allow for optimized working load, while still allowing vegetation establishment. The termination plate is selected based on the anchor size and cabling configuration. The small termination is 4" diameter, while the large termination is 6" diameter.

Summary of Typical Assemblies. (Alternate configurations available, tendons can be offered in zinc-aluminum or stainless steel.)

Swipe left to view all data.

| Assembly/Part |

F80-X-Z Series |

F120-X-Z Series |

F120-SW-Z Series |

F170-SW-Z Series |

| Cap |

4" Dia. Zinc Alloy |

4" Dia. Zinc Alloy |

6" Dia. Zinc Alloy |

6" Dia. Zinc Alloy |

| Grip |

Spring-Loaded Ceramic Crush Roller |

Spring-Loaded Ceramic Crush Roller |

Spring-Loaded Ceramic Crush Roller |

Spring-Loaded Ceramic Crush Roller |

| Cable |

1/8" Dia. ZA Coated Steel, 3 ft. Typ. |

1/8" Dia. ZA Coated Steel, 6 ft. Typ. |

1/4" Dia. ZA Coated Steel, 6 ft. Typ. |

1/4" Dia. ZA Coated Steel, 6 ft. Typ. |

| Anchor |

Zinc Alloy 3.1" (80mm) x 1.30" (33mm) |

Zinc Alloy 4.7" (120mm) x 1.57" (40mm) |

Zinc Alloy 4.7" (120mm) x 1.57" (40mm) |

Zinc Alloy 6.7" (170mm) x 2.17" (55mm) |

| Anchor Bearing Area |

3.4 in2 (22.0 cm2) |

6.0 in2 (38.7 cm2) |

6.0 in2 (38.7 cm2) |

12.2 in2 (79 cm2) |

| Typ. Working Load |

750 lbs |

750 lbs |

2,500 lbs |

3,000 lbs |

| Max Working Load |

1,300 lbs |

1,300 lbs |

2,700 lbs |

3,500 lbs |

| Ultimate Assembly Strength |

1,500 lbs |

1,500 lbs |

3,000 lbs |

3,800 lbs |

| Ultimate Cable Strength |

2,100 lbs |

2,100 lbs |

7,000 lbs |

7,000 lbs |

| Typical Use |

Workhorse Light Assembly |

Soft Soil Workhorse Light Assembly |

Hard Soil Heavy Assembly |

Standard/Soft Soil Heavy Assembly |

|